Description

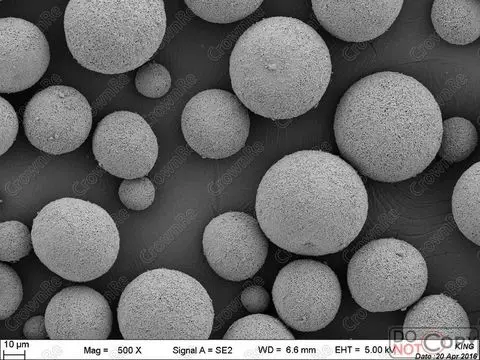

Zirconia series

code

Processing method

ingredient

Characters

Technical parameters

Particle size range (μm)

Coating properties

apply

CN-131

Agglomeration sintering

CaO:5.0

ZrO2: Margin

Nearly globular

white

Melting Point: 2535~2550 °C

HRC=30~45

-50~+20

-45~+15

-40~10

-30~+5

It has moderate hardness, high porosity, excellent thermal insulation, heat resistance and thermal shock resistance.

It is used as a high-temperature gas erosion resistant and thermal barrier coating for rocket nozzles, engine combustion chambers, internal combustion engine combustion chambers, gas turbines and other components.

CN-132

Agglomeration sintering

CaO:10.0

ZrO2: Margin

Nearly globular

white

CN-133

Agglomeration sintering

Y2O3:8.0

ZrO2: Margin

Nearly globular

white

Melting Point: 2480°C

HRC=35~45

-50~+20

-45~+15

-40~10

-30~+5

The coating is dense and tough, resistant to high-temperature particle erosion,

Excellent thermal shock resistance and good thermal insulation.

used as a thermal barrier coating for rocket and jet engine combustion chambers, gas turbine blades, and internal combustion engine combustion chambers;

high-temperature, particle-resistant erosion-resistant coating for missile nose cone and rocket nozzle;

Anti-thermal shock and anti-bonding coating for brazing and heat treatment fixtures.

CN-134

Agglomeration sintering

Y2O3:13.0

ZrO2: Margin

Nearly globular

white

CN-135

Agglomeration sintering

Y2O3:20.0

ZrO2: Margin

Nearly globular

white

CN-136

Agglomeration sintering

Y2O3:2.5

CeO2:25.0

ZrO2: Margin

Nearly globular

Black-brown

Melting Point: 2480°C

HRC=35-45

-50~+20

-45~+15

-40~10

-30~+5

Excellent for use in thermal barrier applications with harsh environments;

At higher temperatures, the 8% yttrium-oxide stabilized zirconia coating has greater resistance to corrosion of sodium, sulfur and chlorine contaminants.

Product name: YAG

Material name: yttrium aluminum garnet (YAG) powder

Chemical precipitation method: 10-100um, irregular shape, high crystal phase purity.

Solid phase method: 15-45um spherical shape, good fluidity, mainly used for thermal spraying plasma spraying;

Ingredient ratio: 3Y2O3:5Al2O3 Y3AL5O12

YAG(wt%):≥ 99.9%

Powder color: white

Molecular weight 593.7

Crystal structure Cubic crystal

Hardness 8-8.5

Melting point 1950°c

Density 4.55g/cm3

YAG, is the abbreviation of yttrium aluminum garnet, the chemical formula is Y3Al5O12, is a composite oxide formed by the reaction of Y2O3 and Al2O3, belonging to the cubic crystal system, with garnet structure. The unit cell of garnet can be seen as a network of dodecahedron, octahedron and tetrahedral.

Storage method:

This product should be sealed and stored in a dry and cool environment, not suitable for long-term exposure to the air, to prevent agglomeration by moisture, affecting the dispersion performance and use effect, and should avoid heavy pressure, do not contact with oxidants, and be transported according to ordinary goods.

- Cerium zirconium solid solution

- three-way catalysis

- plasma spraying

- yttrium oxide

- zirconia

- titanium oxide

- niobium oxide

- gamma alumina

- automobile exhaust purification

Production Capacity:

20000

Delivery Timeframe:

Within 60 Days

Incoterms:

CFR - Cost and Freight

Packaging Details:

ISO

More about

CrownRe Materials Corp.

100-200

Employees

10M - 50M

Sales volume (USD)

30%

% Export sales

Year

Established

Business type

- Industry / Manufacturer

Keywords

- Catalytic materials

- new ceramic materials

- thermal spraying ceramic materials

- exhaust gas purification materials

- etc

Contact and location

-

CrownRe ********

-

+86 1********

-

淄博 / 山东 | China