Description

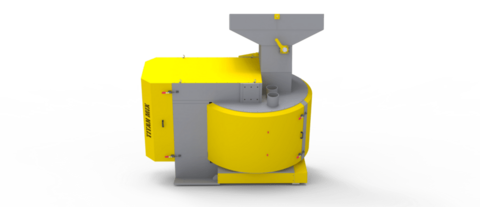

TITAN iM Intensive Mixers — precision blending for powders, slurries & pastes

TITAN iM mixers deliver fast, repeatable mixing for mineral blends, dry-cast and concrete recipes, ceramics and refractories, fertilizers, battery compounds, and more. The core design pairs an eccentric high-energy mixing tool with a rotating pan and wall/bottom scrapers that keep every particle in motion—short cycles, excellent homogenization, and low wear.

Configurations for every process

iMR series (inclined mixing pan): versatile for mixing, granulating, plasticizing, kneading, and coating; available with tilting pan and large service doors for quick clean-outs.

iMWT series (tilting pan with openable cover): fast interior access for changeovers and maintenance.

iMH series (horizontal pan): optimized for liquids, slurries, and highly viscous masses (slips, ready-mix plasters, pastes).

Two operating modes—co-rotating or counter-rotating tool vs. pan—let you tune shear and residence time to the recipe while preventing de-mixing, even with components of different densities.

Process toolkit & options

Vacuum execution for degassing, evaporation cooling, and vacuum drying

Heating & cooling via jacketed pans (from hot-air to induction heating options)

Dust-tight designs for hazardous or explosive powders

Drive packages from robust standard motors to high-torque solutions

Sensors, cleaning & accessories

Moisture, temperature, force, and rheology probes for closed-loop quality control; visual monitoring and sampling hardware for quick checks

High-pressure rotary wash nozzles and dry blow-out units for rapid cleaning between batches

Built to last in abrasive duty

Choose wear packages matched to your raw materials: ceramic tiles, vulcanized rubber linings, multi-layer hardfacing, stainless steels, and tungsten-carbide plates for tools and high-impact pan zones.

Operator-friendly by design

Large service doors and adjustable service positions make tools and the pan easy to reach; automated wet or dry cleaning is available to keep downtime low.

Sizes & capacity range (examples)

From lab to plant scale, batch or continuous, atmospheric or vacuum:

iMR 5: 3–5 L (lab/pilot)

iMR 09: ~150 L / up to ~240 kg

iMR 12: ~250–500 L options

iMR 16: ~600–900 L options

iMR 24: ~2,250–3,000 L

iMR 28: ~4,000–5,500 L

iMR 33: ~6,000–8,000 L

iMD W40: ~12,000 L industrial scale

Turn-key mixing systems

TITAN supplies complete prep lines—silos and vessels, belt/screw/pneumatic conveyors or skip hoists, weighing and dosing, and advanced controls with SCADA, condition monitoring, remote maintenance, and online documentation/spares.

Proving the recipe

Pilot trials and process development are available in TITAN’s test facility; every run is recorded and documented to de-risk plant design and scale-up.

Short listing blurb

TITAN iM Intensive Mixers — high-energy, short-cycle mixers with co-/counter-rotating flow options, vacuum/heating/cooling packages, industrial wear protection, smart sensors, and turn-key integration from lab to 12,000 L. Built for reliability, easy cleaning, and consistent quality—batch or continuous.

- intensive mixer

- Eirich mixer

- high-shear mixer

- inclined mixer

- high-energy mixer

- concrete mixer

Production Capacity:

Not informed

Delivery Timeframe:

Not informed

Incoterms:

Not informedPackaging Details:

Not informed

More about

Titan Machinery

50-100

Employees

2M - 10M

Sales volume (USD)

60%

% Export sales

Year

Established

Business type

- Industry / Manufacturer

- Representative / Agent

- Business Service

Keywords

- brick machine

- brick making machine

- block machine

- block making machine

- tile machine

- tile making machine

- concrete brick machine

- concrete block machine Ver Mais

Contact and location

-

Roman ********

-

+48 50********

-

Gdańsk / | Poland