Description

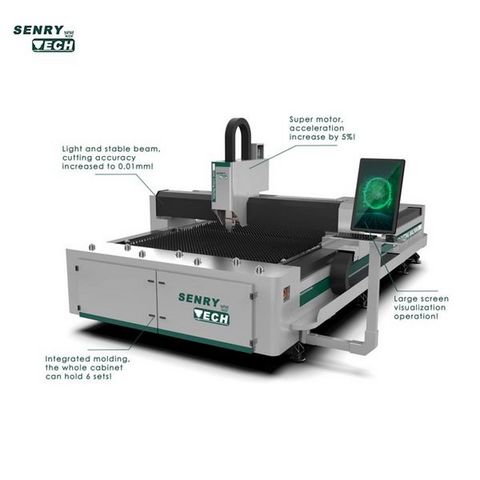

The following is a detailed parameter introduction of the Senrytech optical cutting machine model 1530:

I. Appearance and Dimensions

The Senrytech optical cutting machine model 1530 has a compact and sturdy appearance design. Its worktable size is 1500mm×3000mm. The overall floor area is moderate and can adapt to production workshops of different scales. The machine adopts a high-strength metal frame, and the surface is specially treated, with good corrosion resistance and wear resistance, ensuring stable performance during long-term use.

II. Laser Source

Power: This model is usually equipped with a high-power fiber laser. The power can be selected according to customer needs. Common ones are [specific power value 1], [specific power value 2], etc. The high-power laser source can achieve rapid cutting and improve production efficiency.

Wavelength: Adopting advanced fiber laser technology, the wavelength is stable at [specific wavelength value], with good beam quality and focusing performance, and can accurately cut various materials.

Lifespan: Fiber lasers have the characteristic of long lifespan and can work continuously for tens of thousands of hours, reducing maintenance and replacement costs.

III. Cutting Performance

Cutting speed: For different materials, the Senrytech 1530 optical cutting machine has excellent cutting speed. For example, when cutting thin steel plates, the speed can reach [specific speed value 1] mm/min; when cutting stainless steel plates, the speed is [specific speed value 2] mm/min; when cutting aluminum plates, the speed is [specific speed value 3] mm/min, etc.

Cutting accuracy: The cutting accuracy of the machine is high. The positioning accuracy can reach ±0.05mm, and the repeat positioning accuracy is ±0.03mm. It can meet the processing needs of parts with high precision requirements.

Cutting thickness: This model of optical cutting machine can cut materials of various thicknesses. For example, the maximum thickness of cuttable carbon steel is [specific thickness value 1] mm, the maximum thickness of stainless steel is [specific thickness value 2] mm, and the maximum thickness of aluminum plate is [specific thickness value 3] mm, etc.

IV. Control System

Operation interface: Equipped with an advanced human-machine interface, the operation is simple and intuitive. Users can easily set cutting parameters, view cutting status, and perform fault diagnosis through the touch screen.

Control software: Adopting professional cutting control software with powerful functions. It supports the import of multiple graphic file formats such as DXF, DWG, PLT, etc. The software also has functions such as automatic layout and path optimization to improve material utilization and production efficiency.

Safety protection: The control system has perfect safety protection functions, including laser protection, electrical safety protection, emergency stop button, etc., to ensure the safety of operators.

V. Transmission System

X and Y axis transmission: Adopting high-precision linear guides and ball screws for transmission to ensure cutting accuracy and stability. The transmission system has the characteristics of fast response and high acceleration, and can achieve high-speed cutting.

Z axis transmission: The Z axis can realize automatic focusing and adapt to the cutting of materials of different thicknesses. Adopting precision linear guides and servo motor drive to ensure focusing accuracy and stability.

VI. Auxiliary Equipment

Exhaust system: Equipped with an efficient exhaust system that can timely discharge the smoke and exhaust gas generated during the cutting process and keep the working environment clean.

Cooling system: Adopting an advanced cooling system to ensure that the laser source and optical elements maintain a stable temperature during operation and prolong the service life of the equipment.

Automatic loading and unloading device (optional): According to customer needs, an automatic loading and unloading device can be selected to improve production efficiency and reduce labor intensity.

In conclusion, the Senrytech optical cutting machine model 1530 has excellent performance and parameters and can meet the high-precision cutting needs of various materials. Whether in metal processing, advertising production, mechanical manufacturing and other industries, it can play an important role.

- Fiber Laser Cutting machine

Production Capacity:

1000

Delivery Timeframe:

Within 60 Days

Incoterms:

CIF - Cost, Insurance and Freight

EXW - Ex Works

FOB - Free on Board

Packaging Details:

On pallet

More about

Jinan Senrytech Machinery Co., Ltd

100-200

Employees

50M - 100M

Sales volume (USD)

30%

% Export sales

Year

Established

Business type

- Industry / Manufacturer

Keywords

- Fiber Laser Cutting

- Welding

- Marking

- Cleaning machine

Contact and location

-

Senrytech ********

-

+86 1********

-

Jinan / Shandong | China