Description

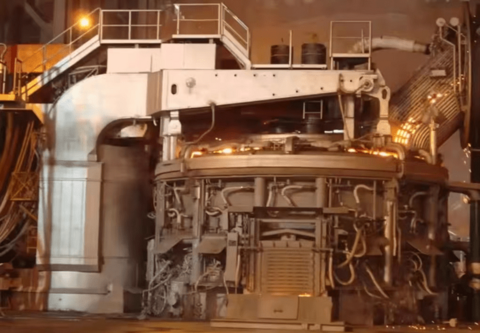

An Electric Arc Furnace (EAF) is a high-temperature metallurgical furnace that utilizes electric arcs generated between graphite electrodes and charged materials to achieve melting and refining.

Industrial arc furnaces range from 0.5-ton foundry units to 400-ton industrial secondary steelmaking systems. The arc temperatures can exceed 3,000°C(5,400 °F), enabling efficient smelting, alloying, and slag-metal reactions under controlled atmospheric conditions.

Electric arc furnaces are classified into regular power, high power, and ultra-high power based on transformer capacity per ton. Offering superior process flexibility, EAFs effectively remove sulfur/phosphorus impurities with precise temperature control in a compact footprint. These characteristics make EAFs ideal for producing high-quality alloy steels.

The main components of this machine are:

Furnace Shell: Refractory-lined steel vessel (split into hearth, slag line, and roof).

Electrode System: Typically 3 graphite electrodes (AC/DC) for arc generation.

Power Supply: High-current transformer and rectifier (for DC EAFs).

Tilting Mechanism: Hydraulic/pneumatic system for tapping and slag removal.

Cooling System: Water-cooled panels (roof, sidewalls, off-gas ducts).

Off-gas Handling: Dust collection (bag filters/scrubbers) and energy recovery.

Process Control: Automated DRI (Direct Reduced Iron)/scrap charging, oxygen lancing, and foamy slag control.

YENENG's Electric Arc Furnace Product Range:

5 ton to 100 ton

- steelmaking Electric Arc Furnace

- EAF

- Industrial Furnace

- Consteel

- HX 5-100

Production Capacity:

Not informed

Delivery Timeframe:

Not informed

Incoterms:

Not informedPackaging Details:

Not informed

More about

Xi'an Yeneng Metallurgical Engineering Co. Ltd

10-50

Employees

2M - 10M

Sales volume (USD)

80%

% Export sales

Year

Established

Business type

- Industry / Manufacturer

Keywords

- Electric Arc Furnace (EAF)

- Submerged Arc Furnace (SAF)

- Refining Furnace (LF)

- VD/VOD/VAD

- Induction Furnace (IF)

- Continuous Casting Machine (CCM)

- Rolling Mill (RM)

- Spare Parts Ver Mais

Contact and location

-

Murphy ********

-

+86 1********

-

Xi'an / 陕西省 | China