Description

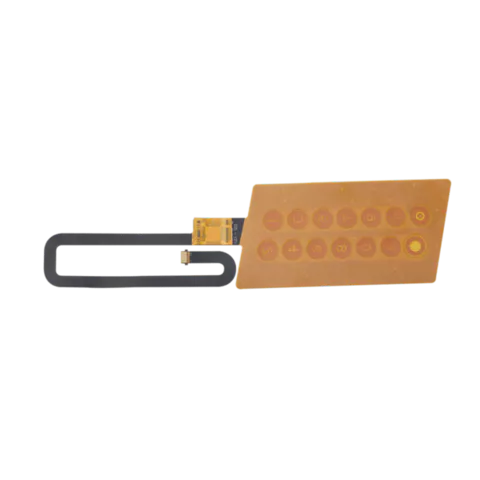

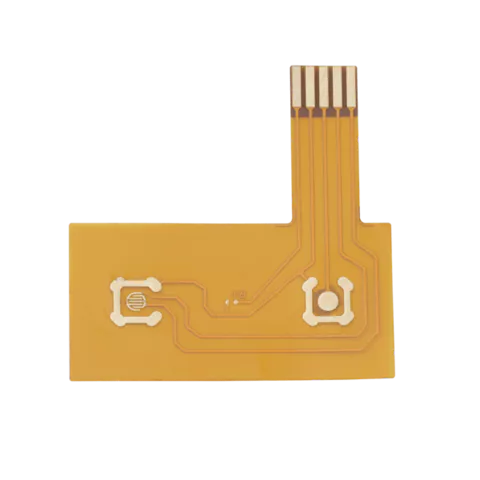

Flexible PCB (Printed Circuit Board) is a circuit board made of flexible substrate and is widely used in membrane switch products. This board is highly flexible and can be bent, folded, and even curled, allowing it to adapt to the needs of a variety of shapes and spaces.

Layer: Double-sided

LINE WIDTH: 0.3MM

LINE SPACING: 0.3MM

HOLE SIZE: 0.2MM

Surface Treatment: Immersion Gold

Color: Yellow

(1) Structural characteristics

1. Substrate selection

- Flexible PCBs typically use polyimide (PI) as the base material, which has excellent resistance to high temperatures, chemicals, and mechanical properties, and is able to maintain stable electrical properties in harsh environments.

2. Copper foil layer

- Thin copper foil is used as a conductive layer to form a circuit pattern through an etching process. The thickness and quality of the copper foil layer directly affect the conductivity and reliability of the circuit board.

3. Overlay

- A protective film, typically polyethylene terephthalate (PET) or PI, is applied to the copper foil layer to protect the circuit from the external environment such as dust, moisture, and mechanical damage.

(2) Application field

1. Consumer electronics

- Flexible PCBs are widely used in consumer electronics such as smartphones, tablets, and wearables to connect displays, buttons, batteries, and other components to achieve a compact internal layout.

2. Medical equipment

- In medical devices such as electrocardiographs, blood glucose meters, etc., the flexibility and reliability of flexible PCBs make them an ideal choice to adapt to the miniaturization and portability of devices.

3. Industrial control

- In industrial control equipment, flexible PCBs are used to connect various sensors, controllers, and displays to maintain stable performance in complex industrial environments.

Second, product advantages

(1) Physical characteristics

1. High flexibility

- Flexible PCBs can be bent, folded, and able to accommodate a variety of shapes and spaces, providing greater flexibility in product design. For example, in wearable devices, flexible PCBs can conform to the curves of the human body and improve wearing comfort.

2. Slim and light design

- Flexible PCBs are thinner and lighter than traditional rigid PCBs, contributing to product miniaturization and weight reduction. In products that require high volume and weight, such as smartphones, flexible PCBs can effectively save space and reduce weight.

(2) Electrical performance

1. High reliability

- The flexible PCB adopts advanced manufacturing process to ensure the stability and reliability of the circuit. In a complex electromagnetic environment, flexible PCB can effectively reduce electromagnetic interference and improve the quality of signal transmission.

2. High-density cabling

- Due to the precision etching process, flexible PCBs can achieve high-density circuit routing to meet the needs of modern electronics for high level of integration.

(3) Environmental adaptability

1. High temperature and chemical resistance

- Flexible PCB substrates (e.g., PI) have excellent resistance to high temperatures and chemicals, and are able to maintain stable electrical performance in harsh environments. In automotive electronics and aerospace, flexible PCBs can withstand high temperatures, high humidity, and chemical corrosion.

2. Vibration and shock resistance

- The flexibility of flexible PCBs allows them to effectively absorb vibrations and shocks, improving the reliability of products in dynamic environments. In automotive engine control systems and industrial automation equipment, flexible PCBs are able to withstand vibration and shock to ensure the proper operation of the equipment.

(4) Cost-effectiveness

1. Reduce assembly costs

- The all-in-one design of the flexible PCB reduces the use of connectors and cables, simplifies the assembly process of the product, and reduces the assembly cost. In mass production, flexible PCB can effectively improve production efficiency and reduce production costs.

2. Extend product life

- Due to the high reliability and environmental adaptability of flexible PCB, it can effectively reduce the failure rate of products, prolong the service life of products, and reduce the maintenance costs of products.

Flexible PCBs offer significant advantages in membrane switch products, making them ideal for modern electronics design and manufacturing due to their high flexibility, thin and light design, high reliability, environmental adaptability, and cost-effectiveness.

- Membrane switch flexible PCB

- membrane switch flexible circuit board

- membrane switch FPC

- flexible PCB

- FPC

- China

Production Capacity:

1000000

Delivery Timeframe:

Depends on Size of Order

Incoterms:

FOB - Free on Board

Packaging Details:

Not informed

More about

Shenzhen Liansheng Electronic Industry Co., Ltd

100-200

Employees

2M - 10M

Sales volume (USD)

60%

% Export sales

Year

Established

Business type

- Industry / Manufacturer

Keywords

- Flexible PCB

Contact and location

-

Zhang ********

-

+86 1********

-

深圳 / 广东 | China