Description

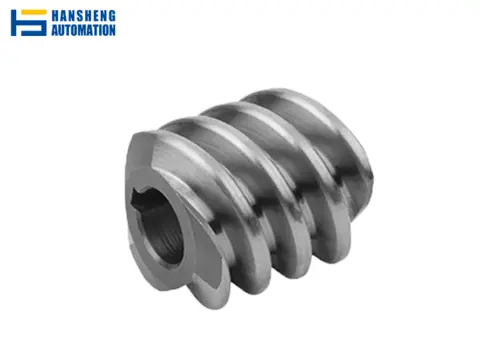

Worm Gear is one of the most common and critical components of packaging machinery. As a packaging machinery parts supplier, Hansheng Automation has successfully delivered a batch of Worm Gear specifically for packaging machinery equipment to a customer in Vietnam. The goods are customized products.

1. Accuracy and performance

The tooth tolerance of the product is ≤ 5 μ m, which reduces backlash by 40% and improves transmission efficiency by 15% compared to traditional ISO level 6 accuracy;

The backlash of the single lead worm gear is 3-5 arc minutes, while the double lead worm gear can be accurately adjusted to 1-3 arc minutes, suitable for high-precision transmission requirements such as servo motors and robot joints.

Through tooth scraping technology and helix angle optimization, the tooth surface roughness Ra is ≤ 0.8 μ m, the operating noise of 1-2 worm gears is less than 60dB (conventional 7-level precision noise ≥ 65dB), and the fatigue life reaches 10 ⁶ cycles (ISO 6-level precision is only 5 × 10 ⁵ cycles). Finite element analysis has verified that the tooth surface contact stress distribution is more uniform and the transmission stability is stronger.

2. Specifications and materials

Standard module range is 0.5-4mm, supporting customized non-standard modules of 0.3-6mm;

The standard reduction ratio is 10-80, and can be customized to 5-100 as needed. The pitch diameter range is 10-160mm (adjusted according to the module and number of teeth).

The material selection includes high-end alloy materials, including phosphor bronze (ZCuSn10Pb1, with a 3-fold increase in wear resistance and strong anti bite ability) suitable for high-strength heavy-duty scenarios (such as machine tool spindles), aluminum bronze (ZCuAl10Fe3) for medium load wear-resistant scenarios (such as conveyor lines), and wear-resistant cast iron for low-speed heavy-duty scenarios (such as mining machinery).

3. Customization capability

Support customization of special tooth profiles such as involute and normal profile, non-standard installation distance (tolerance ± 0.01mm), irregular hole diameters such as keyway/step holes can be machined as needed;

We can also provide anti-corrosion coatings such as Ni-P plating, customized high-temperature alloy materials such as Inconel, and noise optimization solutions such as tooth top shaping.

In addition, the product adopts the "worm wheel worm same line machining" mode to ensure precise matching of tooth surface hardness and higher meshing accuracy. At the same time, it can provide supporting worm machining services (the worm is made of 20CrMnTi carburizing and quenching, with a hardness of HRC 58-62).

4. Application scenarios

The positioning error of the photoresist machine worktable is less than 10 μ m, the rotation axis of the coordinate measuring machine, semiconductor packaging equipment, etc., and the high-speed operating noise is less than 60dB. Medical equipment (surgical robot joints, CT scanner rotation mechanism), aerospace (satellite antenna driven lightweight aluminum bronze worm gear, drone servo motor driven worm gear, with anti vibration design),

And non-standard special scenarios such as electric vehicle reducers, salt spray resistant worm gears for marine engineering, and phosphor bronze worm gears for heavy-duty machine tool spindles.

5.FAQ

What is the practical difference between ISO Grade 5 and Grade 6 precision?

Grade 6 is 0.02mm; the tooth profile inaccuracy of a Grade 5 precision worm gear is ≤0.01mm; so, the backlash may be managed in three arc minutes. Using servo motor drives as an example, ISO 5-grade precision achieves ±0.1° (ISO 6-grade is ±0.3°), appropriate for precision applications such lithography machine stages and surgical robot joints; whereas ISO 6-grade precision is more suitable for general automation equipment.

What is the minimum order quantity for non-standard customization?

Standard module products, non-standard modules (e.g., 0.3 mm/6 mm), or special processes (such as carburizing and quenching, Ni-P plating) all have a minimum order quantity of 5 pieces. Sample production takes 1-2 weeks, and mass production takes 2-3 weeks. Customization based on drawings or samples is supported, and rush orders are available (with samples ready in as little as 1 week).

How to select worm gear material?

Light-load quiet applications (e.g., medical equipment, office machinery): Choose nylon worm gears (noise <55dB, self-lubricating and maintenance-free, compliant with FDA standards);

Medium-load general applications (e.g., conveyor lines, automated equipment): Choose aluminum bronze (ZCuAl10Fe3) (30% lower cost than phosphor bronze, 80% load capacity, high cost-effectiveness);

High-speed heavy-duty applications (e.g., machine tool spindles, electric vehicle reducers): Choose phosphor bronze (ZCuSn10Pb1) (friction coefficient 60% lower than cast iron, suitable for speeds >1000 rpm, strong anti-seizing capability). Q: Do you offer matching worm gear processing services?

Do you provide matching worm gear processing services?

We offer matching worm gear processing services on the same production line, using 20CrMnTi carburizing and quenching (HRC 58-62), precisely matched to the hardness of the worm wheel tooth surface.

- ISO 5 Precision Custom Metal Worm Gear

- Metal Worm Gear

- Precision Worm Gear

- Non-standard Worm Gear

- Double-lead Worm Gear

- High-precision Transmission Worm Gear

Production Capacity:

10000

Delivery Timeframe:

Within 30 Days

Incoterms:

Not informedPackaging Details:

Not informed

More about

Hansheng Automation (Dongguan) Co., Ltd.

10-50

Employees

1

Sales volume (USD)

90%

% Export sales

Year

Established

Business type

- Industry / Manufacturer

Keywords

- Cam Indexers

- Hollow Rotary Tables

- Planetary Gearboxes

- Harmonic Drives

- Gear Manufacturer

- Custom Gears

- ISO 5 Gear Manufacturing

- High-Precision CNC Machining

- Custom CNC Machining

- Precision Castings Ver Mais

Contact and location

-

Karim ********

-

+86 1********

-

东莞市 / 广东省 | China